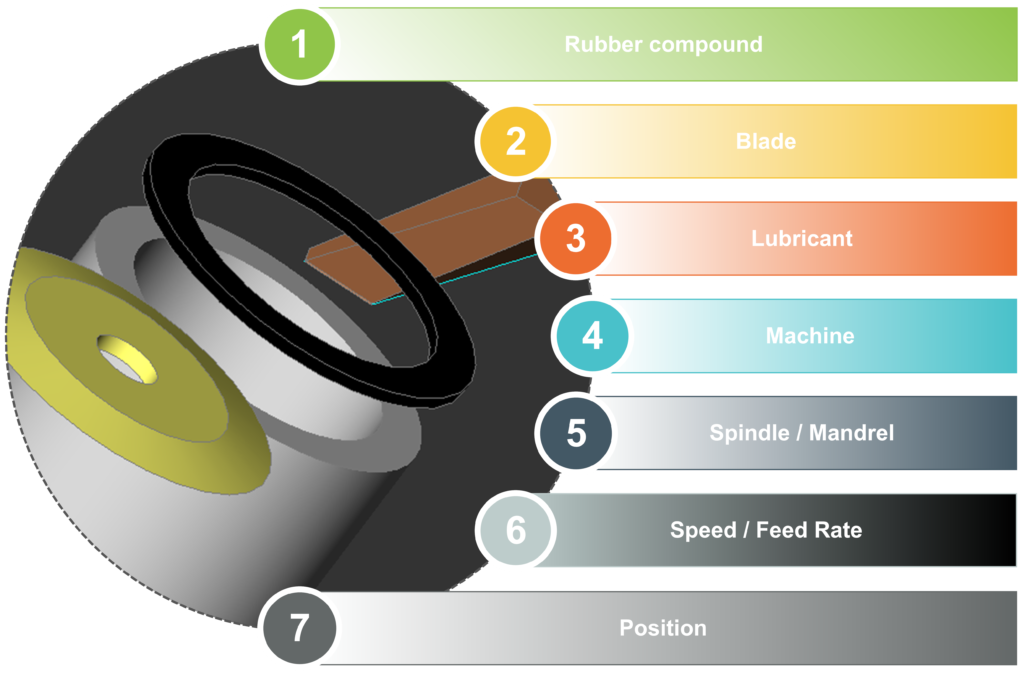

7 keys to perfect lathe cutting of rubber gaskets

- Rubber compound

- High X linking density

- Good ratio between filler and plastisizer

- High tear resistance

- Blade

- Hard surface, treated or Tungsten Carbide

- Fine grains for perfect surface

- Slim (asymmetric cutting angle)

- Circular for best surface, pin ended for high speed

- Lubricant

- Low friction

- Low viscosity (can be even compressed air)

- Environment friendly

- Machine

- Precise

- Solid, low vibration, heavy

- Compact

- Spindle

- Loose or tight fit

- No longitudinal tension (air support)

- Well centered

- Speed / feed rate

- Rpm*dia must fit to compound and blade

- Feed rate in constant relation to speed

- CNC axis better than curved cam control

- Position (of blades)

- Exact orthogonal to hose axis

- Below centre for pin end blades (depending on direction)

- On centre for circular blades

CUTTING GASKETS CUTTING RUBBER GASKETS GASKETS RUBBER GASKETS RUBBER TECHNOLOGY