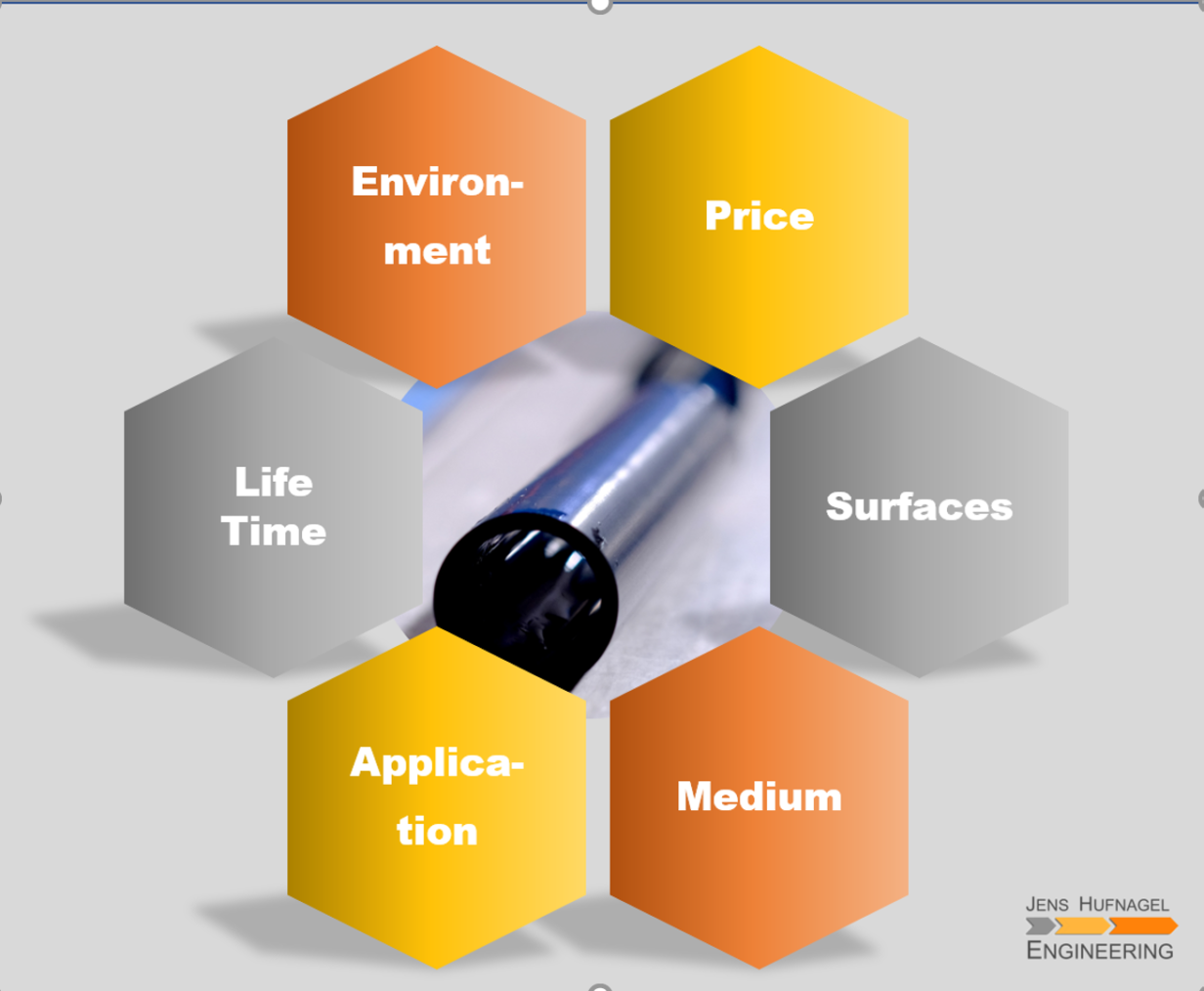

Selecting the right rubber compound

Rubber products are often a cheap commodity. Many describe it by colour and maybe Shore hardness. The failure of a rubber part may lead to unexpected, even lethal consequences.

These are a few factors to be considered when choosing the correct compound:

- Medium

The medium and its pressure defines the choice of polymer. Each polymer type is dedicated to a certain type of media.

- Environment

Especially temperatures and the presence of rays or ozone define the requirements for crosslinking and maybe aging protection.

- Application

Hoses, dampers, gaskets etc have many types of applications. Dynamics require good compression set, sometimes abrasion resistance and / or rebound resilliance.

- Surfaces

Parts in contact with rubber components should be specified regarding their surfaces. A rough or uneven surface needs a softer rubber with good compression set, especially for gaskets / seals.

- Life time

The life time of rubber is limited. Excessive deformation, exposure to ozone or UV radiation are leading to a damage of the matrix. Migration of volatiles is changing the hardness and elastic properties.

- Price

The cost of a rubber compound is mainly defined by its ingredients. Elastomer types have very different prices that can differ by factor 20. Process aids are adding up to that cost structure. Inactive fillers can drive the price down whilst compromising the performance.

There are countless rubber formulations, many historically grown. So when designing a rubber part as a component of your system, bare in mind it might be the cheapest part, but definitely one of the most relevant.