Saving energy and time in steam rubber vulcanisation

Rubber vulcanisation is a high energy process. The consumption of fossil energy carriers is gaining relevance in the overall cost structure plus in environmental aspects. Among the currently available technologies steam curing is one of the oldest but still very efficient and dominating when it comes to mandrel – based hose production.

Set – up

· Choose a high quality boiler with 2 bar extra pressure

· Invest in a good water treatment and pre – heating (with economiser)

· Shorten the distance between boiler and autoclaves

· Rather use smaller autoclaves to shorten change

· Insulate steam pipes

· Use large diameters for exhaust, avoid bendings / turns

Handling

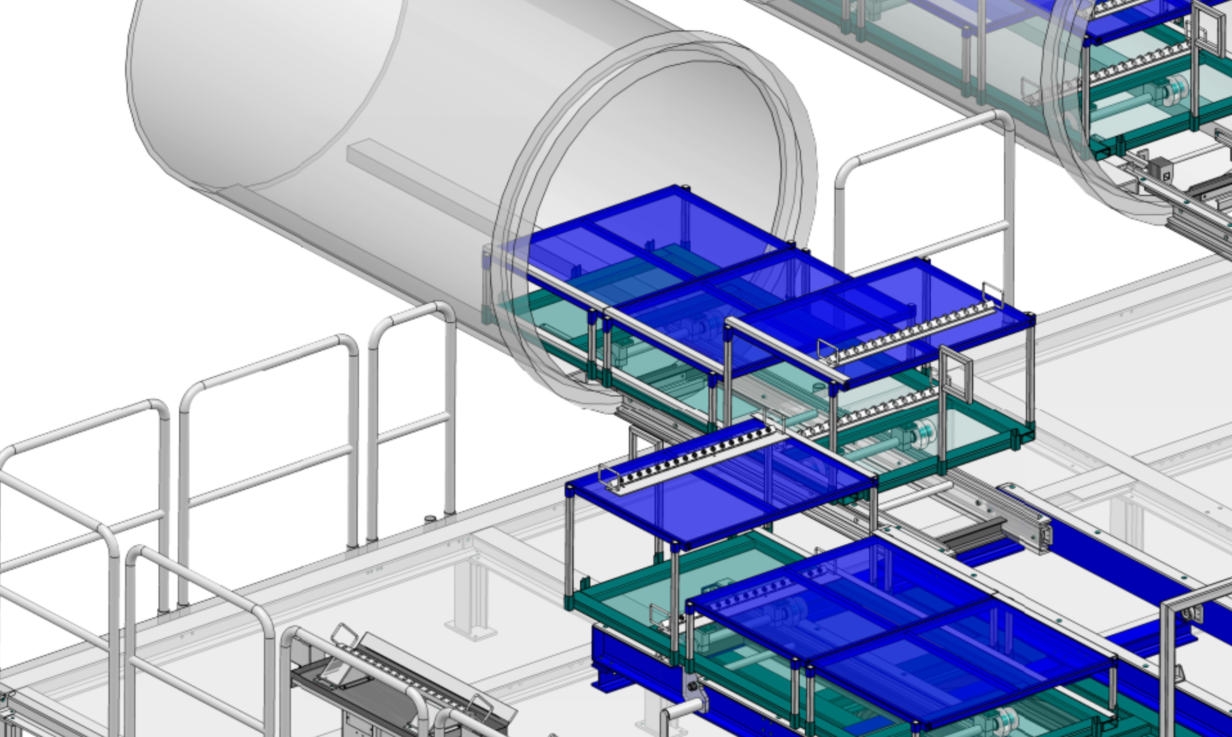

· Use a smart cart handling system for fast change

· Provide good monitoring and maintenance on a daily basis

· Be cautious of condensate

· Makes sure your equipment does not cool down in between cycles

· Target for 24 / 7 operation

· Shorten curing time, minimize safety margins

· Check for sufficient purging